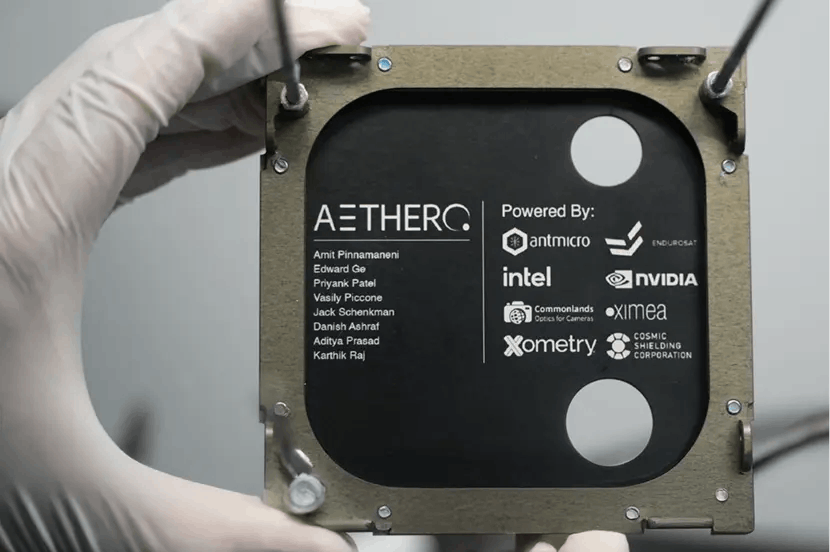

Plasteel

Plasteel® is redefining how hardware performs in orbit. It is unlocking entirely new architectures by protecting COTS GPUs, sensors, and advanced electronics from the harshest radiation environments. It is enabling AI and data systems to operate reliably in orbit, extending mission life and shaping the future of compute in space.

10x

Plasteel® reduces radiation-induced single event effects up to 10x.

180 MeV/n Xe at HIMAC

Nvidia Jetson Orin NX 8GB

7x

Plasteel® keeps missions running up to 7x longer.

63 MeV protons at TRIUMF

Nvidia Jetson Orin NX 8GB

15x

Plasteel® delivers up to 15x cost savings over traditional rad-hard systems.